Our Process

A disciplined, risk-aware approach to dependable hardware product development.

A structured, engineering-led process designed to reduce technical, certification and manufacturing risks — delivering reliable hardware through accountability and diligence.

Years Domain Expertise

Successful Projects

% Repeat Client Rate

Hardware Failures rarely come from Lack of Effort — they come from Unmanaged RISK.

At Teq Diligent, PROCESS is how we MANAGE RISK.

We promise discipline, accountability and predictability.

Hardware Programs struggles when:

✘ Requirements are incomplete or ambiguous

✘ Architecture decisions are rushed

✘ High-speed and EMI risks surface too late

✘ Firmware and hardware are developed in isolation

✘ Validation is treated as a final step

✘ Certification readiness is assumed, not engineered

Our Philosophy

Reliable products are built through diligence — not shortcuts

Every phase of our process emphasizes: Clear ownership | Structured reviews | Early Validations | Risk identification & mitigation | Manufacturing & certification awareness.

Our goal is simple - Reduce Uncertainty and build dependable products

Teq Diligent Development Process

We don’t just design PCBs; we engineer certified, high-performance physical products.

1. Definition & Feasibility

Establishing a clear and realistic foundation

We begin by understanding what must be built — and what could go wrong

What we do:

✔ Requirements and use-case analysis

✔ Environmental and regulatory considerations

✔ Platform and component feasibility

✔ System architecture options

✔ Preliminary BOM and cost outlook

✔ Mechanical and enclosure constraints

✔ Firmware feasibility assessment

Risk Reduced:

✄ Incorrect Platform Selection

✄ Unclear Requirements

✄ Late Architectural changes

2.

Planning & Governance

Creating predictability and accountability

Strong engineering needs strong governance

What we do:

✔ Project plan with milestones and reviews

✔ Defined communication and escalation paths

✔ Single point of accountability

✔ Requirement traceability and change control

Risk Reduced:

✄ Schedule surprises

✄ Scope ambiguity

✄ Communication gaps

3.

Detailed Design & Simulation

Reducing technical risk before fabrication

Design decisions are validated before they become expensive

What we do:

✔ Schematic design with peer reviews

✔ High-speed PCB layout (DDR, PCIe, USB, MIPI, etc.)

✔ Signal and power integrity checks

✔ Thermal considerations

✔ Firmware architecture & early driver work

✔ Mechanical developments

Risk Reduced:

✄ Signal integrity issues

✄ Thermal Failures

✄ EMI/EMC design weakness

4.

Prototyping & Bring-up

Validating assumptions on real hardware

Prototypes are built to reflect production intent.

What we do:

✔ Controlled PCB fabrication and assembly

✔ Visual and workmanship inspections

✔ Power-up and rail validation

✔ Processor bring-up and peripheral checks

✔ Parallel firmware development and debugging

Risk Reduced:

✄ Assembly related issues

✄ Design Issues

✄ Power related issues

5.

Functional & Field Validation

Confirming behavior under real operating conditions

Prototypes validations to check the design intent.

What we do:

✔ Functional testing against requirements

✔ Firmware–hardware integration validation

✔ Edge-case and corner-case testing

✔ Issue tracking and resolution

Risk Reduced:

✄ Functional gaps

✄ Unpredictable behaviors

6.

Environmental & Pre-Compliance Validation

Preparing the product for certification and real-world use

Prototypes validations to check the certification readiness.

What we do:

✔ EMI/EMC pre-compliance checks

✔ Surge, ESD, EFT evaluations

✔ Thermal stress testing

✔ Reliability and endurance testing

Risk Reduced:

✄ Certification failures

✄ Costly redesigns for certifications

7.

Acceptance, Pilot & Certification Support

Bridging Engineering and Production

Design transfer to manufacturing in agreement with all stakeholders.

What we do:

✔ Acceptance testing with stakeholders

✔ Design refinements from validation feedback

✔ Pilot builds (EVT / DVT / PVT)

✔ Certification lab coordination and support

✔ Production documentation handover

Risk Reduced:

✄ Manufacturing instability

✄ Yield issues during production

We are Your Dependable Partner for End to End Hardware Product Developments.

Measurable Reliability: Engineering Outcomes We Delivered

Our Client Successes

Trusted by Global Innovators

Our expertise translates directly into measurable client ROI:

✔ Field Failure Rate: Less than 5% (Ensuring high reliability)

✔ Launch Success: Minimize costly re-spins and launch delays

✔ Cost Savings: BOM cost savings through optimized design

✔ Strategic Value: Act as your trusted, long-term design partner

We have delivered reliable hardware and firmware for billion-dollar Test & Measurement companies, SMT line instrument companies in the USA and specialized government organizations, including ISRO.

Case Studies

High Speed Data

Acquisition System

64 channel CCD data acquisition system is designed around Xilinx’s Kintex Ultrascale FPGA to run image processing algorithms.

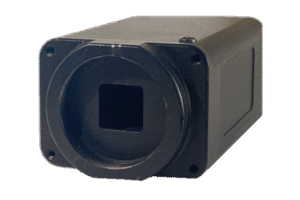

Machine Vision

Camera

5MP CMOS camera is a platform which captures raw images and streams these images over Gigabit Ethernet

Biometric Access

Control System

Android based Biometric device with 800MHz ARM CPU, DDR3 memory, Ethernet, WiFi and other interfaces.

12 Years of

Deep

Experience

100+

Projects

Delivered

70%

Repeat

Customers

Global Delivery

India | USA | Singapore

Ready to build your Reliable, Certified and Scalable Hardware Product?